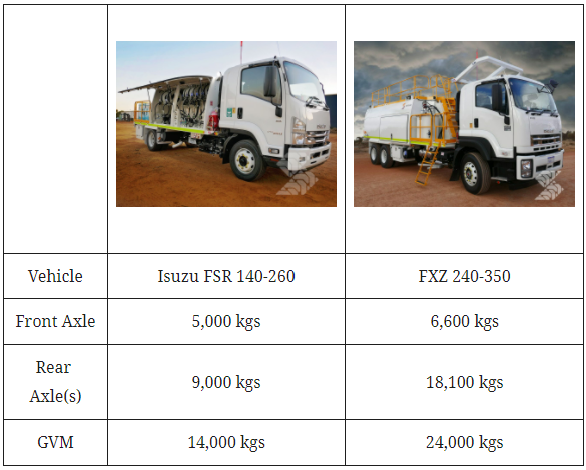

Weight distribution is the amount of the total vehicle weight imposed on the ground at an axle, group of axles, or an individual wheel. The weight on a truck must be distributed on the axles to comply with the chassis manufacturer’s axle ratings and weight laws.

Axle capacities are limited either by the axle capacity or legal weight limits, whichever is lower. In addition to axle capacities, the Gross Vehicle Mass (GVM) is the maximum operating weight of the vehicle specified by the manufacturer, which takes the cab and chassis, engine, and every other component of the truck into account.

The centre of gravity of an object is a hypothetical point at which weight is evenly dispersed and all sides are in balance. Each truck component, including passengers and cargo, have a centre of gravity.

In physics, “moments” are a force or weight times a distance. Moments provide a way to combine several components or items to calculate a centre of gravity for them as a group. When the centre of gravity is known for all items combined, it is possible to calculate the weight on each axle.

From a vehicle owners’ perspective, it is important to match the capacity of the truck to the weight it is expected to carry. An overloaded truck is unsafe and illegal but if a truck consistently hauls less than its capacity, the owner is not realising a full return on investment and operating costs will be higher than they should be.

In addition to being illegal and the risk of penalties, improper weight distribution and overloading cause excessive wear and premature failure of parts, unsafe operation such as compromised directional control and insufficient braking capacity and additional stresses that may be instrumental in causing the frame to crack or break.

Careful consideration must be given to distribution of the load weight to determine how much of the total, including chassis, cab, body, and payload, will be carried on the front axle and how much will be carried on the rear axle, and the total. Moving components a few inches forward or backward on the chassis can mean the difference between acceptable weight distribution for the truck or an application that will not do the job satisfactorily.

Headquartered in regional Western Australia, Shermac has been designing and manufacturing high quality, engineered-for-purpose mobile equipment in the mining, civil and commercial sectors since 2002.

If you have a technical query or would like to discuss your next project, call our team on 1300 799 943 or email [email protected] with your inquiry.